Thermoforming as a design tool in printed-electronics applications Paid Members Public

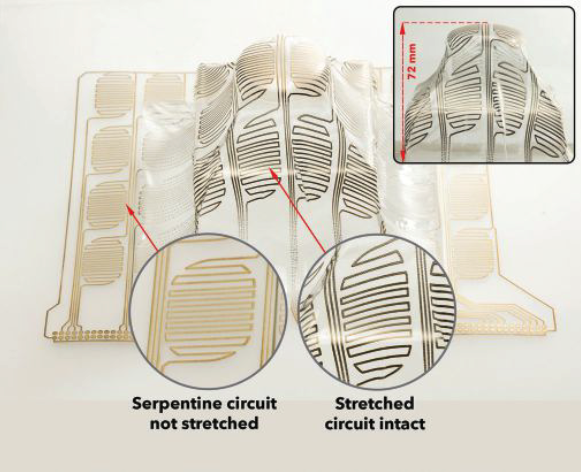

To date, the benefits of two-dimensional (2D) printed electronics have been widely realized when the printed flat components can be integrated into the target device without many design constraints. However, it often can be challenging to fit the printed 2D surfaces fully conformally onto complex surfaces of a 3D device,

The basics of web trim slitting Paid Members Public

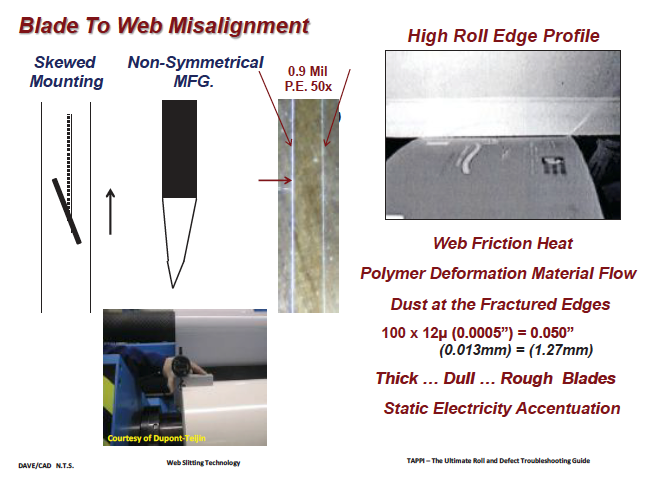

Why do we trim slit webs? To paraphrase the late Professor Erwin Cory, “That is a two-part question. Why? is a question that has plagued mankind since time immemorial.” Secondly, do we trim slit webs? That answer is yes. One of the reasons we trim slit is to remove baggy

Technology Watch Q4 2022 Paid Members Public

Recycle-ready PP laminate resists chemicals, fits pharma applications Constantia Flexibles (Vienna, Austria) launches PERPETUA ALTA, the first ready-to-be-recycled, monomaterial substrate based on polypropylene (PP) with high chemical resistance for pharmaceutical products. The new addition within the co.’s “Design for Recycling” guidelines is said to withstand aggressive liquid or gel

Substrate Secrets: Why, why and how do we measure substrate properties? Part 4 Paid Members Public

My last column focused on control charts, which are how we effectively use and understand the measurements we make and their impact on product quality. Now let’s get back to some film measurements. We already looked at film appearance, so the topic that I will focus on now will

Special Market Report: Printed & Flexible Electronics Paid Members Public

In this issue: * Tech Forecast: Are printed & flexible electronics finally on a roll? * "Gap Analysis" helps industry advance business, technology * Ellipsometry on flexible substrates * Thermoforming as a design tool in printed-electronics applications * Thermoset film offers soft, high-temperature-resistant stretchability: Part 1 Click the link below to download the

Photoinitiated addition-cure for silicone-release coatings: Part 2 Paid Members Public

Silicone (polydimethylsiloxane) polymers are unique materials that are chemically inert and of low polarity that remain fluid at temperatures as low as -120° C and retain useful properties at temperatures >250° C for extended times. Cross-linked silicone polymers can be bulk-solid elastomers, rubbers, gels and low-surface-energy coatings capable of

MARKET MONITOR | Aseptic food-packaging demand up 5.5% a year to $2.3 billion in 2026 Paid Members Public

It’s not just for your grandparents’ shelf-stable chocolate milk anymore. If anything, the applications for aseptic food packaging have grown far and wide since the material-converting method and sterile filling-process technology first became commercial about 75 years ago. Today, everything from cooking stocks and broths to ready-to-eat soups, sauces

How proper treatment for flexible laminates helps achieve high bond strength, zero optical defects Paid Members Public

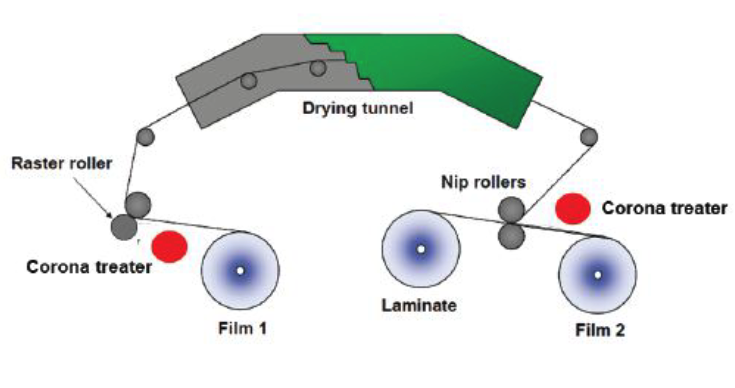

This article discusses the main criteria for high-quality lamination used in today’s flexible packaging sector and the role that surface treatment plays with sophisticated substrates. Lamination requires two essentials: bond strength and zero visual defects. Fundamental to both is the need to understand the part played by surface tension