Substrates

How Do We Balance "Trust" with "Suspicion" on Base Substrates Paid Members Public

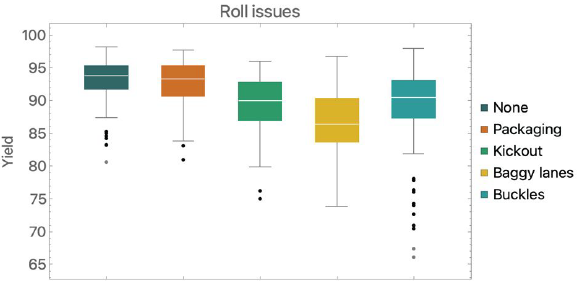

Everyone who applies coatings worries about the coating process. But when it comes to the base substrate (film, foil, paper, etc.), people either are too trusting or too suspicious. None of us happen to suspect the base only when it is a problem...

How Do We Balance "Trust" with "Suspicion" on Base Substrates? Paid Members Public

Everyone who applies coatings worries about the coating process. But when it comes to the base substrate (film, foil, paper, etc.), people either are too trusting or too suspicious. None of us happen to suspect the base only when it is a problem...

Substrate Secrets: What, why and how do we measure substrate properties? Part 3 Paid Members Public

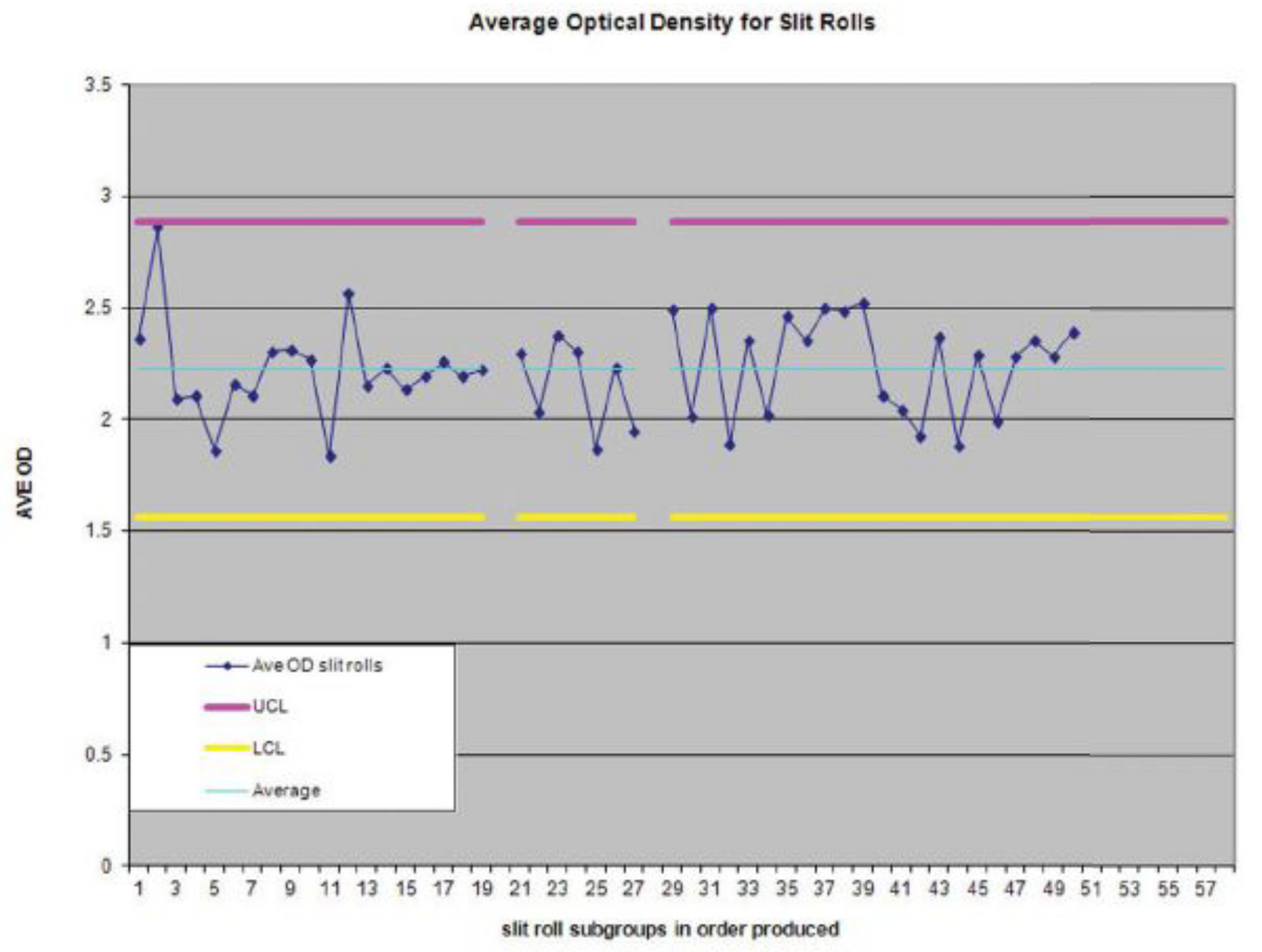

As I have said before, substrates harbor many secrets. Some are easy to discern; some are not. Critical properties should be measured and controlled to ensure accurate property levels are met or known. I will continue with what properties should be measured, along with a discussion on how to use

Substrate Secrets: Why, why and how do we measure substrate properties? Part 4 Paid Members Public

My last column focused on control charts, which are how we effectively use and understand the measurements we make and their impact on product quality. Now let’s get back to some film measurements. We already looked at film appearance, so the topic that I will focus on now will

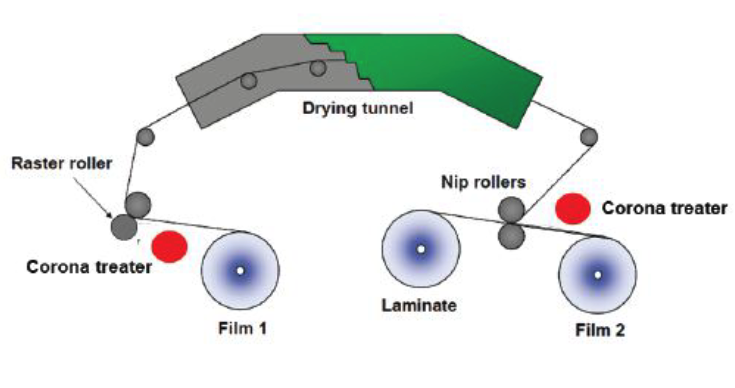

How proper treatment for flexible laminates helps achieve high bond strength, zero optical defects Paid Members Public

This article discusses the main criteria for high-quality lamination used in today’s flexible packaging sector and the role that surface treatment plays with sophisticated substrates. Lamination requires two essentials: bond strength and zero visual defects. Fundamental to both is the need to understand the part played by surface tension

SUBSTRATE SECRETS | What, why, and how do we measure substrate properties? Part 1 Paid Members Public

Substrates harbor many secrets. Some are easy to discern (such as haze and gloss), while others (such as barrier, tensile strength or heat-sealing properties) can’t be known by simple visual appearance. However, they should all be measured to ensure accurate property levels are met or known. But which properties