Printed/Flexible Electronics

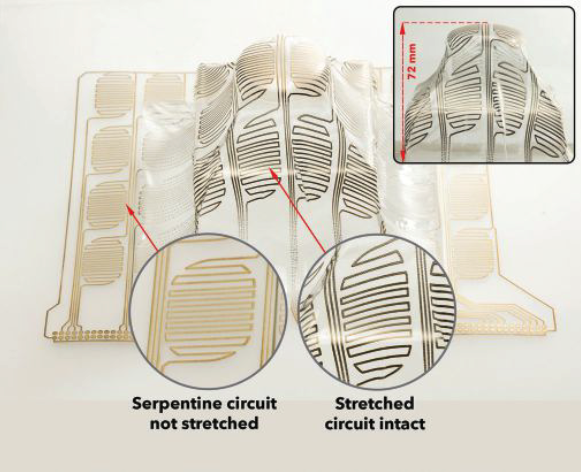

Thermoset film offers soft, high temperature-resistant stretchability for printed electronics: Part 1 Paid Members Public

A primary factor limiting the deployment of printed electronics is a dearth of application-specific substrates. Conventional thermoplastic polymer films like TPU and PET, typically employed for printed electronics, exhibit poor temperature resistance and relatively high hysteresis, creating significant challenges for printing and curing of functional materials, such as conductive pastes,

Thermoforming as a design tool in printed-electronics applications Paid Members Public

To date, the benefits of two-dimensional (2D) printed electronics have been widely realized when the printed flat components can be integrated into the target device without many design constraints. However, it often can be challenging to fit the printed 2D surfaces fully conformally onto complex surfaces of a 3D device,

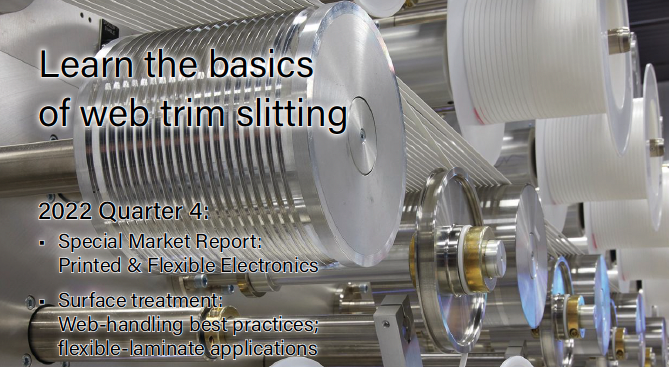

Special Market Report: Printed & Flexible Electronics Paid Members Public

In this issue: * Tech Forecast: Are printed & flexible electronics finally on a roll? * "Gap Analysis" helps industry advance business, technology * Ellipsometry on flexible substrates * Thermoforming as a design tool in printed-electronics applications * Thermoset film offers soft, high-temperature-resistant stretchability: Part 1 Click the link below to download the

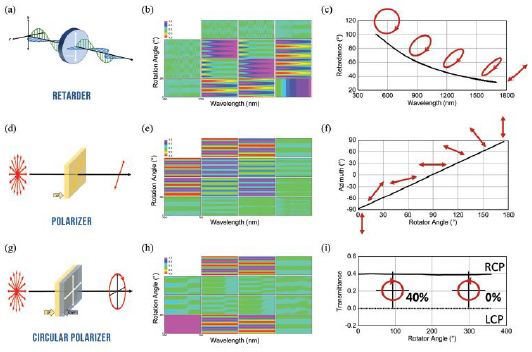

Ellipsometry on flexible substrates Paid Members Public

Modern electronics are becoming thinner, lighter, more conformable, bendable or rollable. You now can fold your smartphone to fit in small pockets. You can wear your electronic devices to check email or monitor your daily physical activity. Augmented, Virtual and Mixed Reality (AR/VR/MR) devices allow you to experience

Converting Quarterly | Q4 2002 Paid Members Public

Click the link below to download the full article.

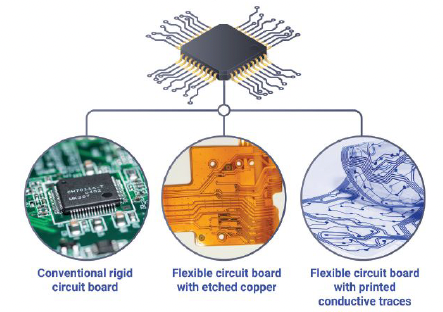

Are printed & flexible electronics finally on a roll? Paid Members Public

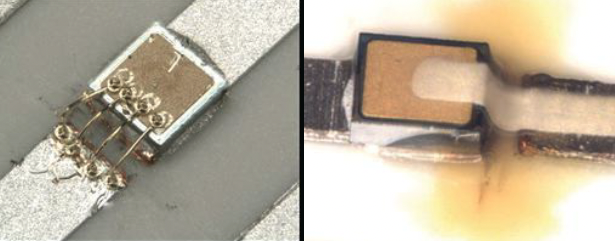

Printing electronics as easily as newsprint has long been a compelling vision, promising cheaper circuits, sensors, solar panels and even displays. Known as roll-to-roll (R2R) electronics, it uses conductive and other functional inks printed onto flexible substrates. However, for many applications, R2R electronics has been held back by difficulty incorporating

“Gap analysis” helps advance business, technology for flexible, hybrid, printed electronics Paid Members Public

SEMI FlexTech has been championing business and technology development of the flexible, hybrid, printed and organic electronics sector for 20+ years as the industry expanded to more than US$50 billion, with significant growth on the way. Driven by demands in mobile phones, automotive, flexible power, IOT devices, e-textiles, displays,

Integrated Printing Solutions Paid Members Public

Ben Robesin, SPGPrints America, Inc. Roll to roll screen printing for solar panels, batteries, floor heating, wide coating & finishing, electronic printing, biosensors, industrial applications, wallpaper, security printing. Widths available are from 10" to 55". Full line available as well as integration into existing equipment https://www.youtube.