polymer films

Polymer structure, mist control, tailored release all key factors in high-speed silicone coating for p-s label converting & use Paid Members Public

Silicone suppliers must continue to focus on the new trends and drivers that challenge our current technologies. There is a strong market need for higher production effi ciency to improve cost and sustainability, and these advancements in coating and converting processes require silicones to evolve to address new requirements. Mist

Photoinitiated addition-cure for silicone-release coatings: Part 1 Paid Members Public

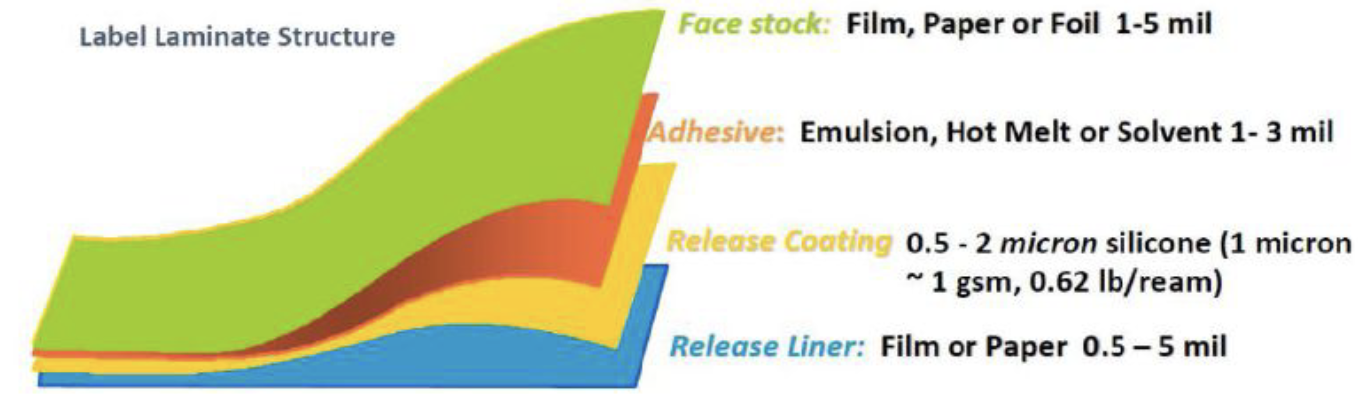

Silicone (polydimethylsiloxane) polymers are unique materials that are chemically inert and of low polarity that remain fl uid at temperatures as low as -120° C and retain useful properties at temperatures >250° C for extended times. Cross-linked silicone polymers can be bulk-solid elastomers, rubbers, gels and low-surface-energy coatings capable

Thermoset film offers soft, high temperature-resistant stretchability for printed electronics: Part 1 Paid Members Public

A primary factor limiting the deployment of printed electronics is a dearth of application-specific substrates. Conventional thermoplastic polymer films like TPU and PET, typically employed for printed electronics, exhibit poor temperature resistance and relatively high hysteresis, creating significant challenges for printing and curing of functional materials, such as conductive pastes,