Coating

Electron-beam curing for battery production offers potential solutions Paid Members Public

It is no secret that batteries have become intrinsic to everyday life. Batteries have made mobile technology possible – from the flashlight to the Walkman to the cellphone – and, in turn, technology has demanded battery development keep pace.

Coating-process digitalization opportunities created by absolute, in-process, coating-thickness measurement data Paid Members Public

This article discusses some of the coating-process digitization opportunities created by real-time measurement of coating-thickness measurement data, especially by using a precise and absolute thickness-measurement technology known as ruggedized optical interference (ROI) technology.

Alternatives to nuclear sensors for on-line web-gauging of weight / thickness measurement Paid Members Public

The traditional method for the on-line measurement of extruded / cast films, extrusion coatings, solution and hot-melt coatings and nonwovens has been the use of one or more Beta Transmission Sensors.

Roll-to-Roll Production of Perovskite Solar Cells Paid Members Public

Presented by Thad Druffel, University of Louisville The perovskite technology has been touted as a huge economic opportunity because the thin films can be deposited using low temperature solution phase processes that can be easily scaled to roll-to-roll platforms. The Conn Center for Renewable Energy Research has been exploring the

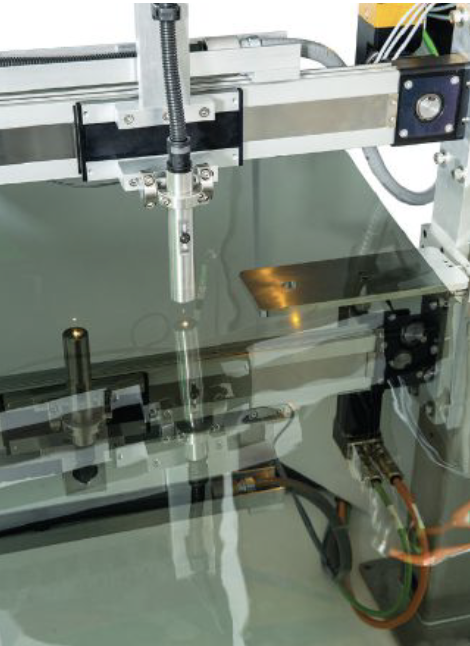

Rapid Thin Film Structure Development Enabled by Advanced R2R Equipment Design, Automation and In-Situ Monitoring Paid Members Public

Presented by Mike Simmons, Intellivation Mike Simmons, Intellivation, Loveland CO Mark George, Plasma Thin Films, Phoenix AZ Development of vacuum deposited layers for new applications requires a transition from small volume (sheets, wafers) to larger volume roll to roll (R2R) while maintaining process parameters and precision deposition. The ability to

Raising Automation of Web Coating to the Next Level – Closed loop full layer stack control in optical and other applications Paid Members Public

Presented by Carsten Deus, VON ARDENNE GmbH The talk introduces the concept of using the insitu sensoric information for a continuous closed loop control of the performance of complex layer stacks, using all the knobs and parameters that an experienced operator would use, for the case of web coating, employing

Energy Solutions in R2R Vacuum Coating Paid Members Public

Presented by Michael Muecke, Bühler Leybold Optics The consumption of energy in general as well as the reduction of the CO2 footprint are two of the most challenging topics of human civilization. The presentation will discuss a set of solutions in roll to roll coating technology, provided to improve environmental