The role of new system-level simulation in solving difficult web-handling design problems

Due to increased demand for consistent quality and faster turnaround times when ordering new web-handling systems, machine designers are turning to simulation to stay ahead of the competition. Simulation models that include dynamical aspects have the advantage over manual calculations...

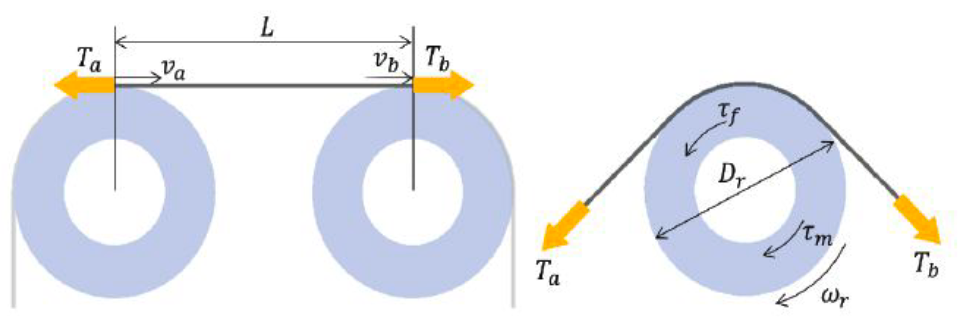

Due to increased demand for consistent quality and faster turnaround times when ordering new web-handling systems, machine designers are turning to simulation to stay ahead of the competition. Simulation models that include dynamical aspects have the advantage over manual calculations in that they can reflect the physical system as it changes during operation. As the process engineer seeks to reduce harmful web behaviors (e.g., slippage and wrinkling) caused by tension-control issues or roller misalignment, having a virtual method to determine when and where they may occur makes the system more robust. In this article, we present a modeling approach for roll-to-roll (R2R) systems that gives a convenient alternative to working with physical prototypes or running validation tests in a production environment. We introduce R2R-system modeling and simulation and show how it is used in identifying slippage, wrinkling and roller alignment problems.

This post is for paying members only

SubscribeAlready have an account? Log in