Adhesives, Coatings & Substrates

How Do We Balance "Trust" with "Suspicion" on Base Substrates Paid Members Public

Everyone who applies coatings worries about the coating process. But when it comes to the base substrate (film, foil, paper, etc.), people either are too trusting or too suspicious. None of us happen to suspect the base only when it is a problem...

Alternatives to nuclear sensors for on-line web-gauging of weight / thickness measurement Paid Members Public

The traditional method for the on-line measurement of extruded / cast films, extrusion coatings, solution and hot-melt coatings and nonwovens has been the use of one or more Beta Transmission Sensors.

What key slitting factors impact the handling of adhesive webs? Paid Members Public

When it comes to Adhesive Web Slitting, there are two different worlds … Science and Manufacturing (see Figure 1). Science deals with creating the many, many different adhesives to be applied to the very large variety of manufactured, flexible-web materials. The two main adhesive-web application types that the converting industry deals

Coating Concepts: Product-process integration: What is the right coating method? Part 1 Paid Members Public

There are three common ways to pick a coating method: inertia, flowcharts and screening tables. The practical advantages of inertia speak for themselves. However, the use of removable-cartridge coaters has reduced the barriers to change. Also, it often is more economical to find a contract manufacturer with the “right” method

Photoinitiated addition-cure for silicone-release coatings: Part 2 Paid Members Public

Silicone (polydimethylsiloxane) polymers are unique materials that are chemically inert and of low polarity that remain fluid at temperatures as low as -120° C and retain useful properties at temperatures >250° C for extended times. Cross-linked silicone polymers can be bulk-solid elastomers, rubbers, gels and low-surface-energy coatings capable of

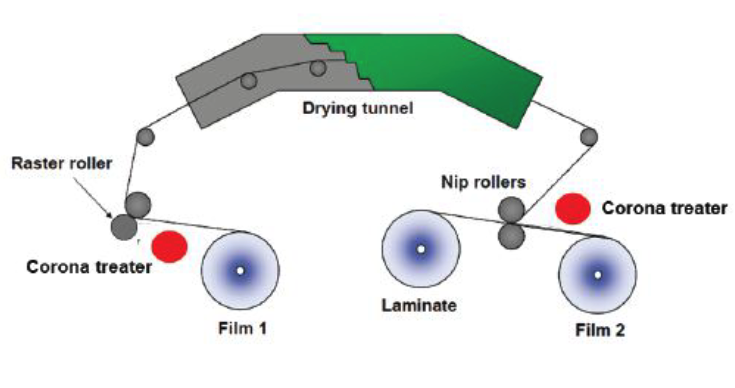

How proper treatment for flexible laminates helps achieve high bond strength, zero optical defects Paid Members Public

This article discusses the main criteria for high-quality lamination used in today’s flexible packaging sector and the role that surface treatment plays with sophisticated substrates. Lamination requires two essentials: bond strength and zero visual defects. Fundamental to both is the need to understand the part played by surface tension