Ted Lightfoot

How Do We Balance "Trust" with "Suspicion" on Base Substrates Paid Members Public

Everyone who applies coatings worries about the coating process. But when it comes to the base substrate (film, foil, paper, etc.), people either are too trusting or too suspicious. None of us happen to suspect the base only when it is a problem...

How Do We Balance "Trust" with "Suspicion" on Base Substrates? Paid Members Public

Everyone who applies coatings worries about the coating process. But when it comes to the base substrate (film, foil, paper, etc.), people either are too trusting or too suspicious. None of us happen to suspect the base only when it is a problem...

Coating Concepts: Product-process integration: What is the right coating method? Part 1 Paid Members Public

There are three common ways to pick a coating method: inertia, flowcharts and screening tables. The practical advantages of inertia speak for themselves. However, the use of removable-cartridge coaters has reduced the barriers to change. Also, it often is more economical to find a contract manufacturer with the “right” method

Regimes of Reverse Gravure Coating Paid Members Public

Presented by Ted Lightfoot, Ted Lightfoot LLC Gravure coating has a reputation for being unpredictable. This is largely because, beside the different configurations of gravure coating (direct, offset, reverse, kiss), there are several different regimes of coating for each configuration. The regime depends on the nature of the substrate, the

COATING CONCEPTS | Product-process integration: What is the right coating method? Part 2 Paid Members Public

The previous installment in this series covered the first step in choosing a coating method: flowcharts and screening tables. Here, we turn to the next two steps: pilot tests and fine-tuning to get a more robust process. Click the link below to download the full article.

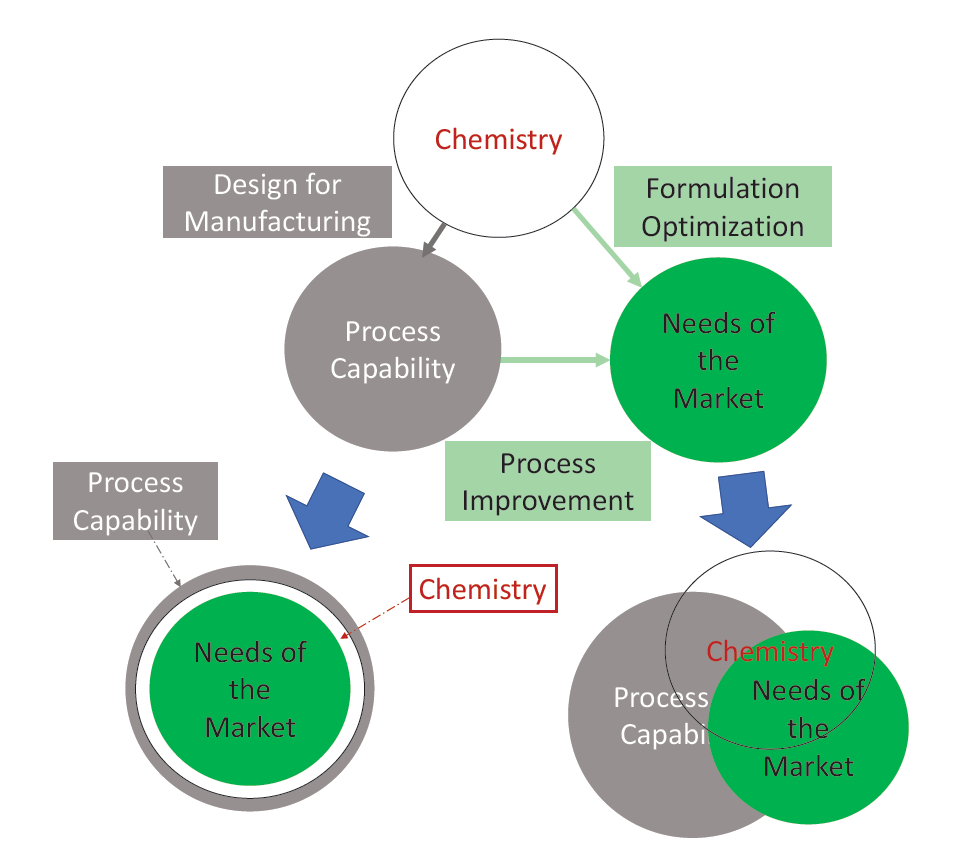

COATING CONCEPTS | Explain the concept of product-process integration in web coating Paid Members Public

One aspect of product-process integration is ensuring the formulation will run on the coater. Sometimes this is called “Design for Manufacturing.”

Classification and Effects of Variations in Fiducial State of a Coating Substrate Paid Members Public

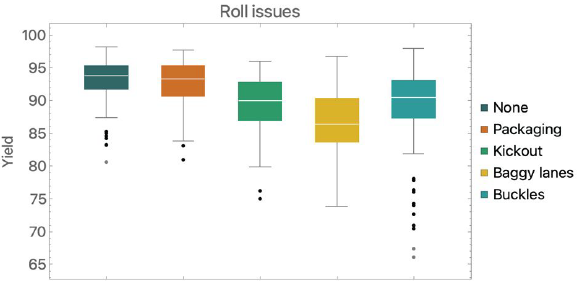

Non-planarities (also known as bagginess, layflat issues, or planarity issues) are known causes of coating upsets and other defects that arise from variations in the fiducial state of the coating substrate.