Coating Methods

How Do We Balance "Trust" with "Suspicion" on Base Substrates? Paid Members Public

Everyone who applies coatings worries about the coating process. But when it comes to the base substrate (film, foil, paper, etc.), people either are too trusting or too suspicious. None of us happen to suspect the base only when it is a problem...

Coating-process digitalization opportunities created by absolute, in-process, coating-thickness measurement data Paid Members Public

This article discusses some of the coating-process digitization opportunities created by real-time measurement of coating-thickness measurement data, especially by using a precise and absolute thickness-measurement technology known as ruggedized optical interference (ROI) technology.

Alternatives to nuclear sensors for on-line web-gauging of weight / thickness measurement Paid Members Public

The traditional method for the on-line measurement of extruded / cast films, extrusion coatings, solution and hot-melt coatings and nonwovens has been the use of one or more Beta Transmission Sensors.

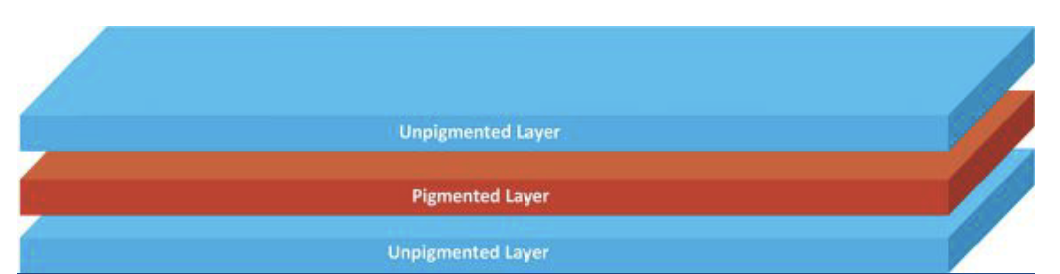

Extrusion coating vs. adhesive lamination: A comparison study Paid Members Public

Both adhesive lamination and extrusion coating can be used to provide a structure for flexible packaging. The question of which method to use often is based on what asset is available, not what system will be best for a given structure. This article will look at the reasons an adhesive

Coating Concepts: Product-process integration: What is the right coating method? Part 1 Paid Members Public

There are three common ways to pick a coating method: inertia, flowcharts and screening tables. The practical advantages of inertia speak for themselves. However, the use of removable-cartridge coaters has reduced the barriers to change. Also, it often is more economical to find a contract manufacturer with the “right” method

COATING CONCEPTS | Product-process integration: What is the right coating method? Part 2 Paid Members Public

The previous installment in this series covered the first step in choosing a coating method: flowcharts and screening tables. Here, we turn to the next two steps: pilot tests and fine-tuning to get a more robust process. Click the link below to download the full article.

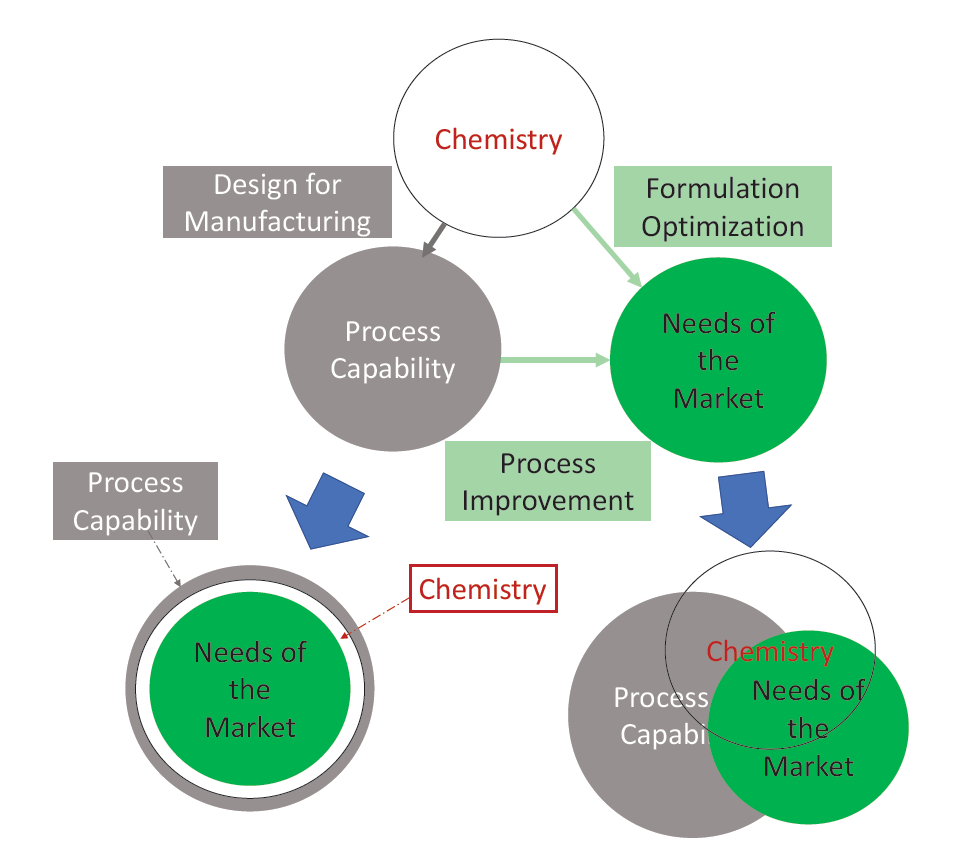

COATING CONCEPTS | Explain the concept of product-process integration in web coating Paid Members Public

One aspect of product-process integration is ensuring the formulation will run on the coater. Sometimes this is called “Design for Manufacturing.”